drive shaft coupling lubricant

The drive shaft is also known as a Cardan shaft propeller shaft or prop shaft. If the U-joint is correctly installed the lube fitting will.

Syn Tech Ns 3913 G1 Dark Brown Gear And Coupling Grease 170 Gram 6 Oz Tube Skygeek

The manual only lists engine coupler spline grease and gives part number 92-802896A 1.

. Add lubricant to universal joint until clean lubricant appears at all four bearing seals and until lubricant appears at pressure relief hole for spline lubrication on VA shafting series 2300 thru 2395 have lube for life slip sections. Continue squeezing grease in until grease begins to extrude out the u. Part 5 of 6.

This side is connected to the main drive shaft through this coupling and on its right is tail drive shaft of helicopter. Our 4 standard spider type jaw coupling with its curved jaw design has no need for lubrication making it a good low maintenence component. A grease reservoir is mounted on one of the shafts to replenish the lubricant required at the spline surfaces.

Iam trying to workout that is it due to loss of lubrication or due to impact. How to check the orientation of the lube fitting in an application. There are three standard drive shaft sizes offered by Power Jacks with ends machined to suit actuator.

Periodically it is greased once a year and then tightened with a o ring packing as well. Rotation of the shafts forces the oil in the grease from the reservoir onto the spline surfaces thereby. Lube pump can be added to most front wheel drive vehicles to enable all four wheels to be towed without damage to your transmission.

Remove the drive coupling from the rotor shaft. Ad Find Couplings For the Job. Up to 8 cash back Step 5.

Look at the drive shaft from the front. One of the splined shafts is coated with a mixture of a solid lubricant and grease. 247 Expert Service Available.

My question in looking at my Clymers is. We offer you Remcos drive shaft coupling. Next I service the final drive.

These are grease pack oil fill and continuous oil flow. NS-3913-G1 is the only lubricant approved by Bell Helicopter Textron for use on their Crown Gear Driveshaft couplings. Oil is normally used as the lubricant in couplings operation over 6000 rpm.

Excellent performance for applications ranging from aerospace such as helicopter drive shaft couplings and bearings to industrial applications such as steel mill gear couplings. Other designs mount external teeth on only one shaft mating with internal teeth mounted to the other shaft. Rotate it so the ears of the yoke on the driving member are vertical North and South.

If there is one use the grease gun to squirt grease into the u-joint. They recommend applying a thick coat of drive spline lubricant to the final drive coupling splines and to the drive shaft splines when I reassemble the two after inspection. Remove the two set screws 48 from each sleeve seal 47 and slide the sleeve off the rotor shaft 43.

The secret to the install is to make sure the drive shaft guy balances the shaft in both positions. When locking and unlocking the driveshaft it can by design end up into one of two positions 180 degrees apart. Remove the trip body 52 Figure 8-5 and rotor locating bearing 50 from the rotor shaft.

A drive shaft coupling 10 where lubricant is to be maintained in a zone of contact between a crown gear 17 and a nested interior annular spline structure 18 which is substantially coaxial to said crown gear 17. Gear Coupling Grease is available from stock in 14 oz. Be sure to consult your Tracto.

The yoke on the drive shaft will be horizontal East and West. Not sure about the 3 and 4 series but the xx10 and xx20 series tractors do not have grease zerks on the driveshaft. It may be necessary while applying grease gun pressure to move drive shaft from side to side to allow.

I ordered the driveshaft with the kit and kept my original driveshaft for later replacement. Theyre also useful when you. I told you wrong I looked in my manual which is for 43 MPI ECT and 50 MPI ECT.

In a rugged aluminium and iron housing the coupling delivers smooth and silent operation in temperatures of -40deg to 90deg. Gear couplings Figure 2 compensate for misalignment via the clearance between gear teeth. Your Power Takeoff PTO Driveshaft needs your attention.

After replacing the coupler once on my 4310 I now take the driveshaft apart to grease it once a year. Reinstall the drive shaft. Trust Genuine Ford Lubricant to deliver excellent load-carrying ability wear resistance and superior protection against rusting and corrosion in your automotive off-highway commercial and high-performance vehicles.

Operating of the lubricant under real services conditions triggers the grease to develop into semi-fluid functionally solash lubricating the wear surfaces with the coupling. Genuine Ford Fluid Lubricant is one of the top-rated Grease for drive shaft slip yoke to meet industrial grade standards. And 5 lb.

If you rarely use fwd I wouldnt worry about it. Pretty straight forward operation. Shaft-mounted external gear teeth on both shafts mate with internal gear teeth on a housing that contains a lubricant.

The coupling mechanical clutch is installed into the rear portion of the cars drive shaft near the rear axle. This coupling condition is freshly removed. I just finished lubing the input splines on my 1980 R100 45k miles.

Remcos Drive Shaft Couplings was developed to provide a quick and easy means of disconnecting the transmission while sitting in the drivers seat. As the grease cools it returns on the unique consistency thereby preventing leakage. There are several methods of lubricating gear couplings.

See how to grease and lubricate your compact tractor PTO Driveshaft. Both grease and oil are used at speeds of 3600 to 6000 rpm. Support structure supports the crown gear 17 and is coupled centrally to the shaft 10.

Remove the rotor assembly from the turbine casing as described in the Removal Section. You can try to google that part number and find a substitute that is available. Install and remove these shaft couplings without disconnecting the shafts motors and other attached components theyre made in two pieces so you dont need to slide them onto shaft ends.

Do this in reverse order. A self-contained lubrication system for a splined high speed drive shaft coupling. Check for a zerk fitting.

This driveshaft coupling was developed to provide a quick and easy means of disconnecting the transmission while youre sitting in the drivers seat. The vast majority of drives operate at 3600 rpm or less and use grease as the lubricant. A drive shaft is a most important part of a vehicle that transfers torque from the transmission to the differential and then the differential delivers this torque to the front wheels to run the vehicle.

It does not list an alternative like it does with engine oil. In simple words the main function of the propeller or drive. However the couplers or a known wear point that will most likely fail over time.

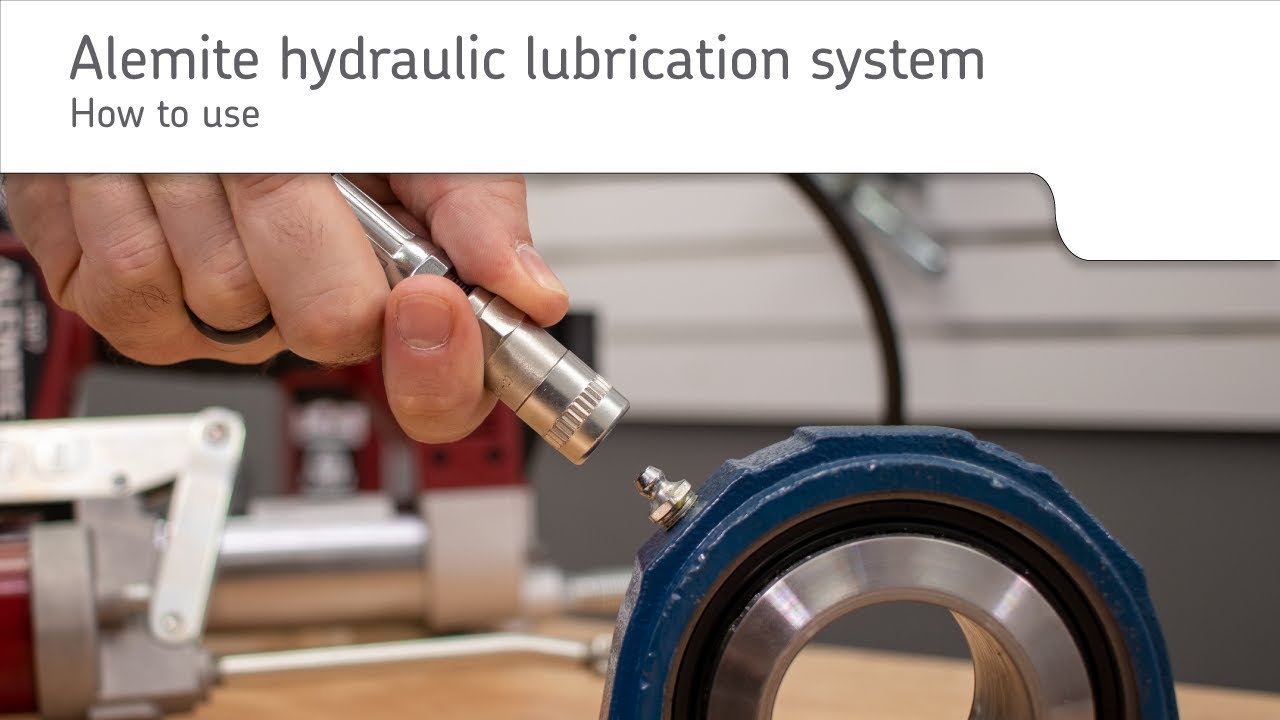

Industrial Lubrication Fittings Alemite Skf

Driveline Lubrication Machine Service Inc

Spicer Driveshaft Lube Torque Specification Spicer Parts Emear

Syn Tech Ns 3913 G1 Dark Brown Gear And Coupling Grease 170 Gram 6 Oz Tube Skygeek

Lmcg 1 Grid And Gear Coupling Grease Skf Skf

How To Lubricate Your Car S U Joints Yourmechanic Advice

Bearing Lubrication A Solution For Every Application Skf

.jpg)

High Performance Commercial Vehicle Grease Industrial Grease

.jpg?auto=compress%2Cformat&height=300&width=555&trim=color&trimcolor=FFFFFF&trimTol=15&ixlib=csharp-3.2.1.0&s=438d330e6523c314e0f7a7e5b98cb7da)

High Performance Commercial Vehicle Grease Industrial Grease

Industrial Lubrication Chesterton Toolbox Essentials

2 4 C Propeller Shaft Lubricant Mercury Quicksilver 802859q1 Free Ship In Us

How To Lubricate A Driveshaft Yourmechanic Advice

Coupling Grease Four Things You Should Know Coupling Answers Where The World Turns For Coupling Knowledge

Spicer Driveshaft Lube Torque Specification Spicer Parts Emear

How To Lubricate A Driveshaft Yourmechanic Advice

Syn Tech Gear And Coupling Grease 6oz Tube 9150 00 506 8497 Ns 391 Pilots Hq Llc

High Performance Commercial Vehicle Grease Industrial Grease